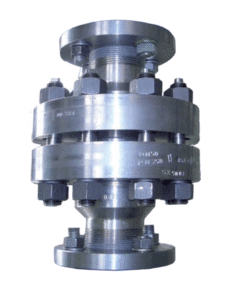

Products Tanker safety valve

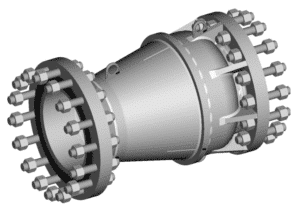

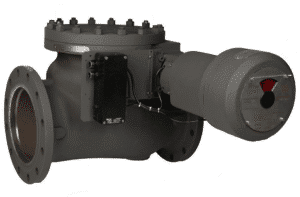

Tanker safety valves for top-loading – The top-loading tanker safety valve is a combination of a spring-loaded ball check valve and a external angle bellow sealed valve. It is pneumatically operated with a fail safe quick-closing valve. Check valve and angle valve are both fitted separately to each other by flanges.

The quick-closing valve is equipped with an intended rupture point. In emergency case the angle valve should break-off without damaging the check valve. The seat of the quick-closing valve is sealed by a tapered disc whilst the check valve is sealed by a ball. The body of the quick-closing valve has a vent hole to verify the efficiency of the bellows.

Tanker safety valve schematic

Tanker top-loading safety valves are conform DIN 26028 for railway tankers and T-11 and T-14 ISO-containers.

The tanker safety valve can configured to handle the following mediums;

- Chlorine – Cl2 (liquid&gas)

- HF – hydrogen fluoride / hydrofluoric acid (liquid&gas)

- Ammonia – NH3 (liquid&gas)

- Butene – C4H8 (liquid&gas)

- Butane – C4H10 (liquid&gas)

- Propane – C3H6 (liquid&gas)

- Iso butane – C4H10 (liquid&gas)

- Sulphur dioxide – SO2 (liquid&gas)

- Vinyl chloride – C2H3Cl (liquid&gas)

- Methyl chloride – CH3Cl (liquid&gas)

- Methyl mercaptan – CH4S (liquid&gas)

- Chlorine carbon monoxide – CO CL2 (liquid&gas)

Please select the type of sampling valve you are interested in.